-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

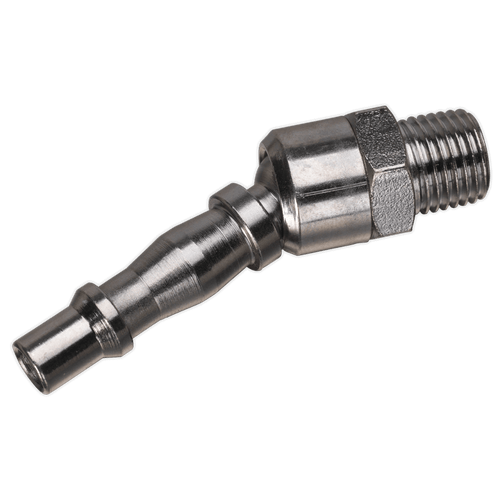

Sealey AC91 Non-Corrodible PCL Coupling Body Male 1/4"BSPT

In Stock

Add to Basket€81.55€67.96 (ex.VAT) -

Draper 25814 1/2" Taper PCL M100 Series Air Line Coupling Female Thread (Sold Lo…

In Stock

Add to Basket€56.92€47.42 (ex.VAT) -

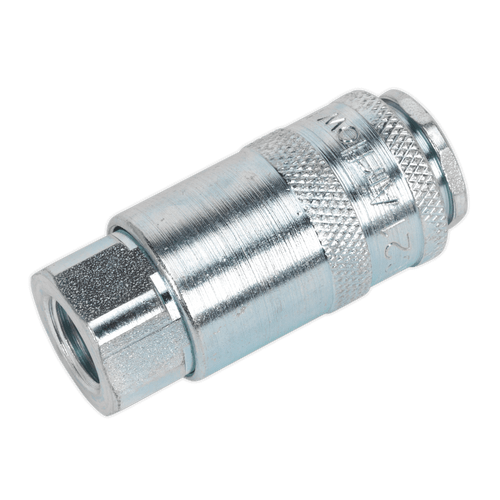

Draper 41879 1/4" BSP Female Parallel' Safeflow' Air Line Coupling

In Stock

Add to Basket€28.43€23.69 (ex.VAT) -

-

-

-

-

-

-

-

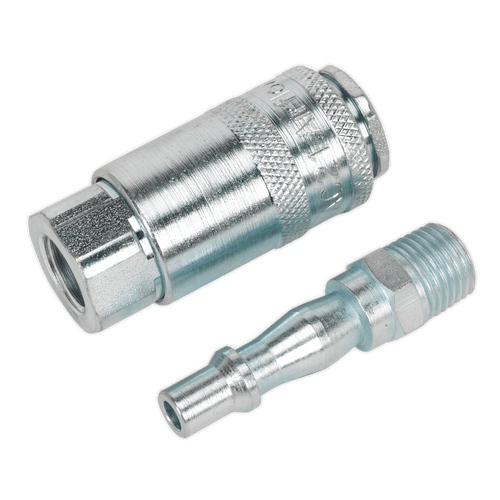

Draper 25855 PCL Twin Standard Coupling with Two Male Couplings and One Tailpiec…

In Stock

Add to Basket€63.13€52.61 (ex.VAT) -

-

Sealey AC07 Adaptor Tailpiece 3/8" Bore Hose Pack of 5

In Stock

Add to Basket€17.84€14.87 (ex.VAT) -

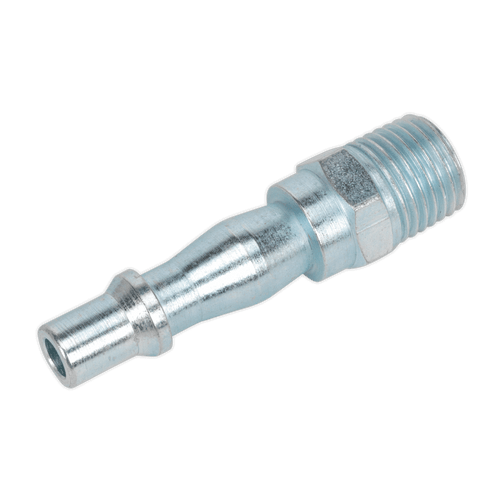

Sealey AC09 Screwed Tailpiece Male 1/4"BSPT - 3/8" Hose Pack of 5

In Stock

Add to Basket€19.90€16.58 (ex.VAT) -

-

Draper 25813 PCL Twin Standard Coupling with Two Male Couplings and One Tailpiec…

In Stock

Add to Basket€54.73€45.61 (ex.VAT) -

Draper 25815 1/2" BSP Male Thread Air Line Coupling (Sold Loose)

In Stock

Add to Basket€49.85€41.54 (ex.VAT) -

-

Sealey AC01BP Coupling Body Male 1/4"BSPT Pack of 50

In Stock

Add to Basket€523.62€436.34 (ex.VAT)

Couplings

A couplings provides a dependable and versatile solution for connecting shafts in a wide array of general-purpose applications. These couplings are engineered for durability and ease of use, ensuring a secure, efficient means of transmitting torque. Designed to accommodate slight misalignments, they help reduce wear and maintain smooth operation in connected equipment. Ideal for use in motors, pumps, and light machinery. They offer a practical and cost-effective solution. With their robust construction and reliable performance, these couplings are an excellent choice for maintaining equipment performance.

Couplings Features:

Very High Airflow

PCL 100‑Series couplings have a large nominal bore (10.3 mm) and are designed to deliver high airflow (≈ 117 CFM / 3,313 l/min). This ensures pneumatic tools operate efficiently with minimal pressure drop, even under demanding conditions.

High Working Pressure

These couplings are rated for a maximum working pressure of 14 bar (200 psi), making them suitable for most industrial and workshop compressed air applications. Their robust construction ensures reliable operation under sustained pressure.

Robust and Safe Construction

Built with a hardened steel shoulder and high-quality materials, these couplings prevent accidental disconnection and withstand rigorous job-site use. They also feature a swivel design to reduce hose kinking, extending the life of hoses and connections.

Wide Operating Temperature

PCL couplings are designed to operate reliably across a broad temperature range (–40 °C to +100 °C), allowing safe use in both extreme cold and heat.

Best Sellers

Kit comprising a male threaded coupling body together with male and female threaded adaptors. Fitted with 1/4" BSP threads. Suitable for most air tool applications.

Splits air supply in two. Compatible with UK-style couplings. Free airflow rate at 100 psi (7 bar): 35-40 cfm (991-1133 L/min).

A swivel adapter allows for greater freedom of movement when connected to an airline. Free airflow rate at 100 psi (7 bar): 35-40 cfm (991-1133 L/min).

FAQs

Are custom couplings more expensive than standard couplings?

No, the engineering process required to create your custom flexure is completely free and is part of our committed service to you. Pricing is a function of the complexity of the design and the material specified.

Do speciality or non-standard couplings take longer to manufacture?

No, just because they are referred to as “non-standard” does not mean that we may not already have these products in our inventory.

What is meant by “single start” and “multiple starts”?

A single start spring is a single continuous coil element that starts at one end and terminates at the other end. This configuration is common to most springs. A “double start” spring has two intertwined continuous coil elements phased 180 degrees apart. In effect, this puts two independent helixes in the same cylindrical plane. Multiple start flexures, such as triple start, etc., are similar extensions of the concept.

What are some of the benefits of multiple start flexures?

Multiple start flexures are beneficial because they not only provide redundant elastic elements should a failure occur, but a failed element (coil) will be physically trapped by the remaining ones.